Key Takeaways:

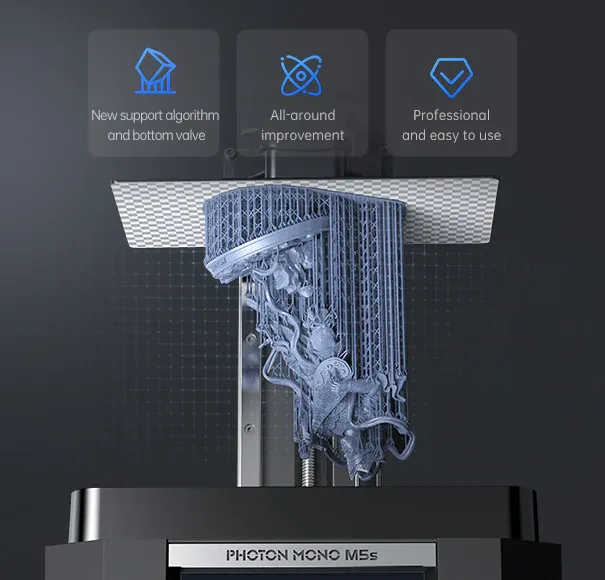

- The Anycubic Photon Mono M5s is a high-speed resin printer that delivers fine details and high-quality prints.

- With its advanced features like the high-resolution LCD screen and intelligent mode, it stands out among other resin printers.

- Proper handling and post-processing are crucial for achieving the best results with the Photon Mono M5s.

Unboxing the Anycubic Photon Mono M5s

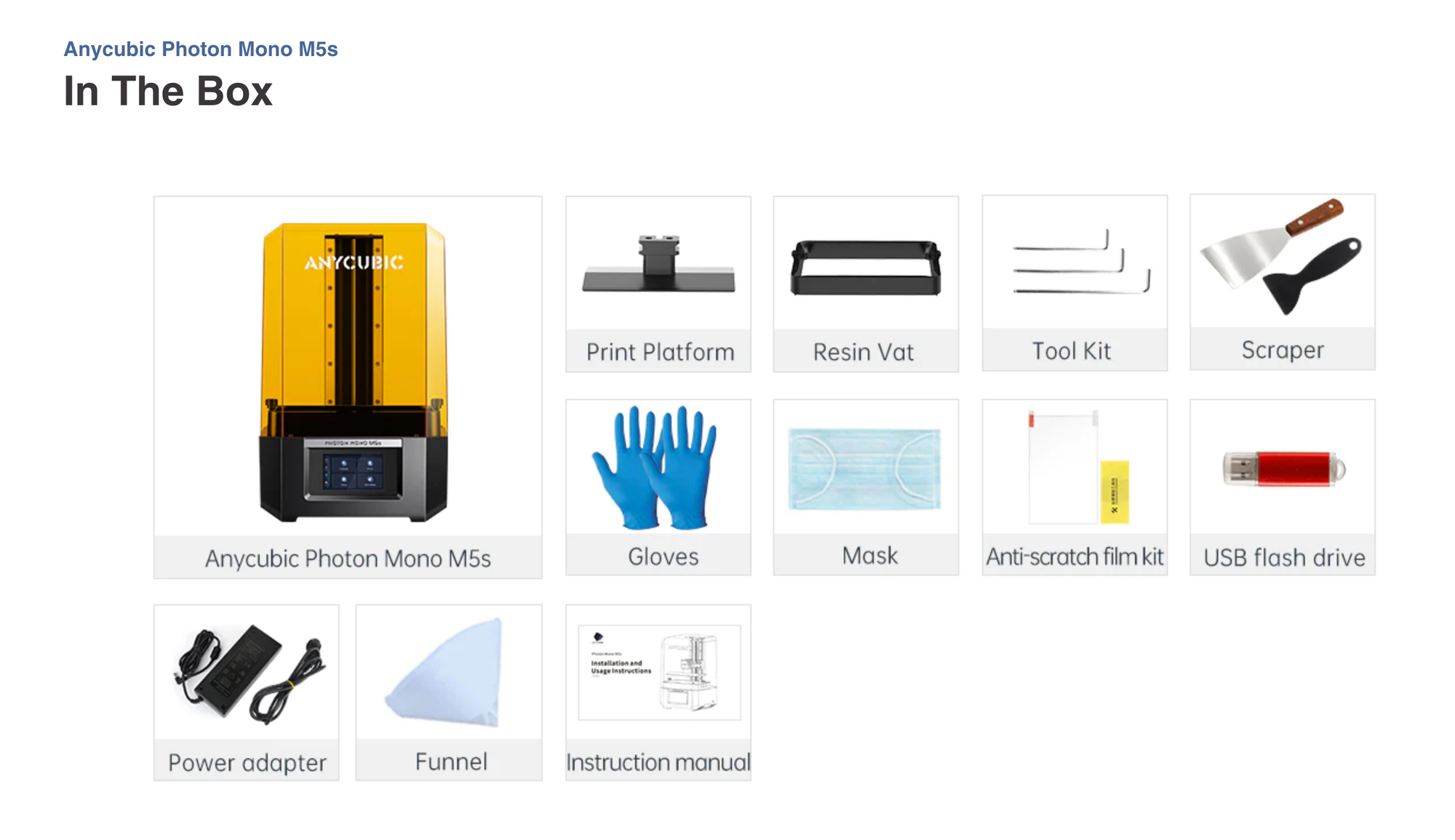

When you receive your Anycubic Photon Mono M5s, the excitement is palpable. As you open the box, you'll find the printer securely packaged, ensuring it arrives in pristine condition. Inside, alongside the machine, you'll discover all the necessary components to start printing: a power supply, a plastic scraper, a resin vat, and a build platform. The unboxing experience is designed to be straightforward, allowing you to set up your new resin printer with ease.

Source: Anycubic.com

Setting Up Your Printer

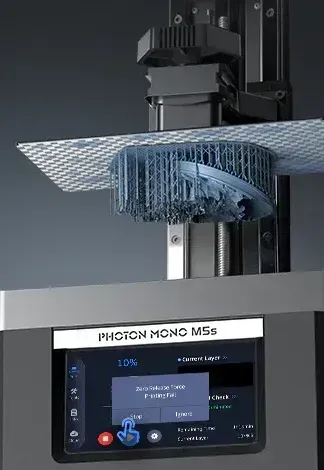

Setting up the Anycubic Photon Mono M5s is a breeze. The build volume is generous, and the build platform is easy to install. Before your first print, make sure to attach the screen protector to the LCD screen to prevent any potential damage from uncured resin. Once the build plate and resin vat are in place, you're almost ready to start printing. Just pour in your chosen resin, and you're good to go.

Understanding the High-Resolution LCD Screen

The high-resolution LCD screen of the Photon Mono M5s is a game-changer. It ensures that each layer of your print is exposed to UV light with precision, resulting in layers that are cured with exceptional detail. This high resolution is what allows the printer to produce prints that boast fine details, surpassing the quality of many other resin printers on the market.

The Intelligent Mode Feature

Anycubic's intelligent mode is a standout feature that simplifies the printing process for both beginners and professionals alike. This mode optimizes print settings based on the model you're printing, reducing user error and ensuring that your prints come out perfectly every time. It's a smart addition that enhances the overall user experience.

Preparing Your First Print

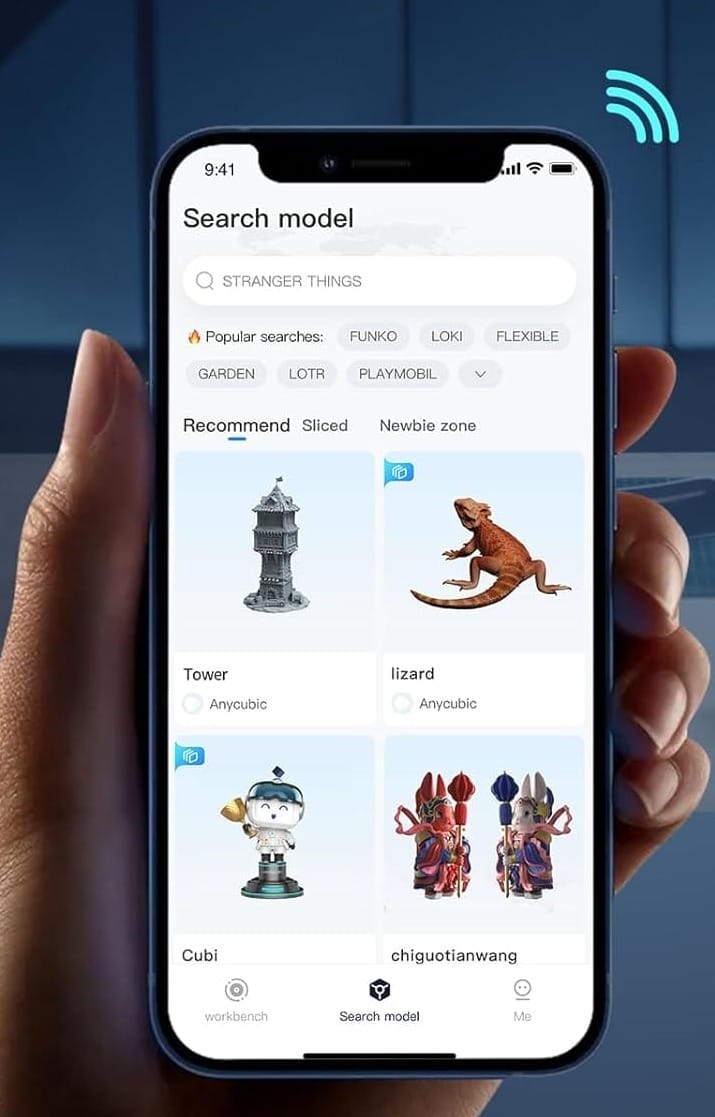

Before you start printing, you'll need to transfer your desired model to the printer. The Photon Mono M5s supports various file transfer methods, including USB and Wi-Fi through the Anycubic app. Once your file is transferred, you can use the touch screen to adjust print settings like layer height and exposure time, tailoring them to your specific project.

The Importance of Layer Height

Layer height is a critical setting that affects both print quality and print time. The Photon Mono M5s allows for fine-tuning of layer height, enabling you to strike a balance between speed and detail. For prints that require high detail, a lower layer height is ideal, while a higher layer height can be used for faster print times on less detailed models.

Speed vs. Detail: Finding the Balance

The average print speed of the Photon Mono M5s is impressive, but it's important to understand that there's a trade-off between speed and detail. For high-quality prints that capture every fine detail, you may need to sacrifice some speed. Conversely, if you're looking for faster results, you can adjust the settings to prioritize speed over detail.

Resin Choices and Their Impact

Not all resins are created equal, and the type of resin you choose can greatly affect your print's outcome. Standard resin is a good starting point, but there are also specialized resins for different applications. The Photon Mono M5s is compatible with a wide range of resins, allowing you to experiment and find the perfect match for your printing needs.

Avoiding Print Failures

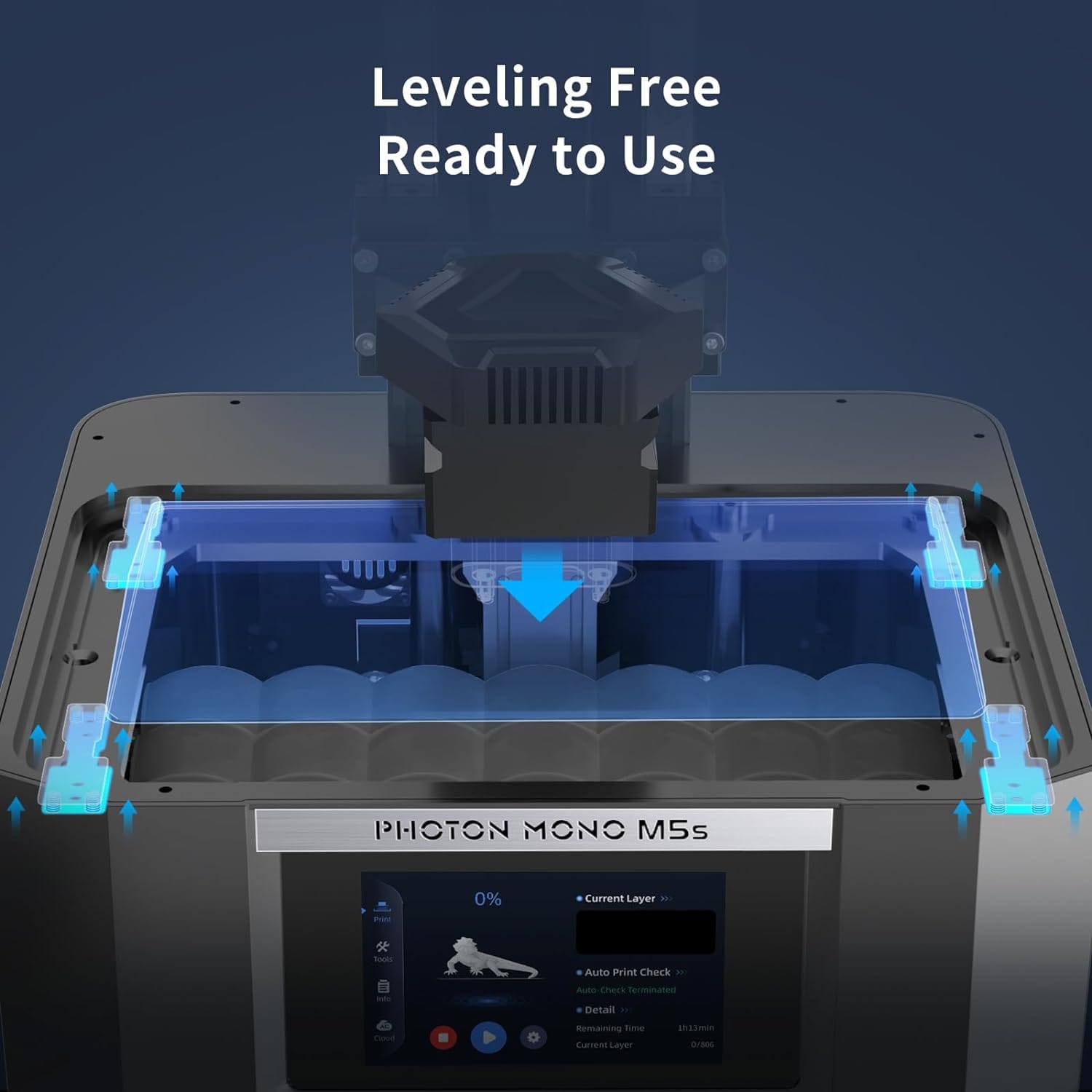

Print failures can be frustrating, but with the Photon Mono M5s, many common issues can be avoided. Ensuring that your build platform is level and that the resin is properly mixed are just a couple of steps you can take to minimize the risk of failures. Additionally, using the right print settings for your model can make a significant difference.

Post-Processing Your Prints

After your print is complete, post-processing is essential to achieve the final high-quality result. This involves removing the print from the build platform, washing off any uncured resin, and curing the print under UV light. Handling uncured prints requires care, so always wear gloves and follow safety guidelines to protect yourself and your prints.

Cleaning and Maintenance

To keep your Anycubic Photon Mono M5s in top condition, regular cleaning and maintenance are necessary. After each print, clean the resin vat and build platform to remove any leftover resin. Check the LCD screen for any resin spills and clean it gently. Proper maintenance ensures that your printer will continue to produce high-quality prints for a long time.

Optimizing Print Settings for Various Resin Types

When diving into the world of resin printing with the Anycubic Photon Mono M5s, understanding how to optimize print settings for different types of resin is crucial. Each resin has its own characteristics, such as viscosity and required exposure time to UV light, which can significantly affect the print quality. For instance, standard resin may require different settings compared to a more specialized castable or flexible resin. By adjusting parameters like layer height and exposure time, users can achieve the fine details and high-quality prints they desire. It's a balancing act that, once mastered, can lead to consistently successful prints.

Professionals and hobbyists alike will find that experimenting with these settings can unlock the full potential of their Anycubic Photon Mono M5s resin printer. For example, a higher exposure time might be necessary for thicker layers or darker resins to ensure proper curing, while transparent resins might need less time under the UV light. Remember to make incremental changes and keep detailed notes for each resin type. This personalized approach to the printing process can help avoid print failures and ensure that every print meets your high standards.

Enhancing Print Quality with Proper Maintenance

Maintaining your Anycubic Photon Mono M5s is just as important as the initial setup when it comes to achieving high-quality prints. Regularly cleaning the resin vat, replacing the release film when necessary, and ensuring the build plate is level can all contribute to the overall success of your prints. A clean and well-maintained printer minimizes the chances of encountering uncured prints or other print failures. It's recommended to wear gloves and use a plastic scraper to remove any residues gently, keeping the vat and build platform in top condition for your next print.

Moreover, the LCD screen, being the heart of your high-resolution printer, requires careful handling. A screen protector can help safeguard against scratches or spills, extending the life of your printer. Additionally, the touch screen interface should be kept free of resin and fingerprints to ensure responsive and accurate control during the printing process. By adhering to a consistent maintenance routine, users can ensure that their Anycubic Photon Mono M5s continues to produce prints with exceptional layer detail and surface finish, making it an excellent choice for both professionals and enthusiasts.

Troubleshooting Common Issues

Even with a high-quality printer like the Photon Mono M5s, you may encounter issues from time to time. Common problems include print adhesion issues or unexpected print failures. Fortunately, the Anycubic community and support resources are available to help you troubleshoot and resolve these issues quickly.

Upgrading Your Printer

The Anycubic Photon Mono M5s is a powerful printer out of the box, but there's always room for improvement. Upgrades like a new release film for the resin vat or a more powerful UV light source can enhance your printing experience. Keep an eye out for official upgrades and community-recommended modifications to take your printing to the next level.

Comparing the Photon Mono M5s to Other Printers

When comparing the Photon Mono M5s to other resin printers, it's clear that it offers a competitive edge in print quality and speed. Its features are tailored to provide a seamless printing experience, and the print results speak for themselves. Whether you're a hobbyist or a professional, the Photon Mono M5s is an excellent choice.

The Anycubic Photon Workshop Software

The Anycubic Photon Workshop is the slicing software designed specifically for the Photon series of printers. It allows you to prepare your models for printing by slicing them into layers and generating the necessary support structures. The software is user-friendly and plays a crucial role in the success of your prints.

Exploring Advanced Printing Features

For those looking to push the boundaries of what's possible with resin printing, the Photon Mono M5s offers advanced features like variable layer height and anti-aliasing. These features allow for even finer detail and smoother surfaces on your prints, giving you the ability to create truly professional-grade objects.

The Role of the Mechanical Sensor

The mechanical sensor in the Photon Mono M5s is a small but significant component that ensures consistent print quality. It detects the precise position of the build platform, allowing for accurate layer exposure. This sensor is one of the many details that contribute to the printer's reliability and performance.

The Anycubic App: Remote Printing Made Easy

With the Anycubic app, you can control your Photon Mono M5s remotely. Start printing, monitor progress, and make adjustments all from your smartphone. This convenience is especially useful for those who need to manage multiple prints or want to keep an eye on their printer while away from the workspace.

Handling Resin Safely

Resin can be hazardous if not handled properly. When working with the Photon Mono M5s, always wear gloves and work in a well-ventilated area. Dispose of uncured resin according to local regulations, and be mindful of your safety and the environment.

The Future of Resin Printing with Anycubic

Anycubic continues to innovate in the field of resin printing, and the Photon Mono M5s is a testament to their commitment to quality and user experience. As the technology evolves, we can expect to see even more advanced features and improved print quality from future models.

Where to Buy the Anycubic Photon Mono M5s

If you're ready to purchase the Anycubic Photon Mono M5s, you can find it on Anycubic's official website, as well as through various online retailers. Be sure to check for the latest deals and promotions to get the best price on your new printer.

Joining the Anycubic Community

Becoming a part of the Anycubic community is a great way to connect with other users, share tips and tricks, and stay updated on the latest news. Join forums, social media groups, or follow Anycubic's social links to engage with fellow enthusiasts and expert reviewers.

Summary

The Anycubic Photon Mono M5s resin printer is a remarkable machine that offers high speed, fine details, and high-quality prints. Its user-friendly features, such as the high-resolution LCD screen and intelligent mode, make it suitable for hobbyists and professionals alike. By following best practices for setup, printing, and post-processing, users can consistently achieve excellent results. Regular maintenance and community support further enhance the printing experience, ensuring the Photon Mono M5s remains a top choice in the world of resin printers.

FAQ Section

Q: What makes the Anycubic Photon Mono M5s different from other resin printers? A: The Anycubic Photon Mono M5s stands out with its high-resolution LCD screen, intelligent mode for optimized printing, and its balance of high speed and fine detail capabilities. These features, combined with its user-friendly interface and reliable print quality, make it a strong competitor in the resin printer market.

Q: How do I ensure the best print quality with the Photon Mono M5s? A: To ensure the best print quality, use the correct resin for your project, level the build platform accurately, and fine-tune the print settings such as layer height and exposure time. Additionally, regular maintenance and proper post-processing techniques are crucial for achieving high-quality prints.

Q: Can I use third-party resins with the Anycubic Photon Mono M5s? A: Yes, the Anycubic Photon Mono M5s is compatible with a wide range of third-party resins. However, it's important to adjust the print settings accordingly to accommodate the specific properties of the resin you choose.

Q: What maintenance routine do you recommend for the Anycubic Photon Mono M5s to keep it in optimal condition?

A: For optimal performance, regular maintenance is crucial. After each print, clean the resin vat and build platform to remove any uncured resin. It's also important to check the FEP film for any damages or resin residues and replace it if necessary. Regularly inspect the LCD screen for any signs of resin spills or scratches and clean it carefully with a soft, dry cloth. Finally, ensure the printer's firmware is always up to date to benefit from the latest features and improvements.

Q: Are there any specific environmental conditions that are best for resin printing with the Anycubic Photon Mono M5s?

A: Yes, environmental conditions can significantly impact resin printing. The ideal temperature for resin printing is between 20°C to 25°C (68°F to 77°F). Humidity levels should be kept low, ideally between 40% and 60%. High temperatures can cause the resin to cure too quickly, while low temperatures may lead to incomplete curing. Additionally, ensure your printing area is well-ventilated to avoid the accumulation of fumes from the resin.

Q: Can the Anycubic Photon Mono M5s print with flexible or castable resins, and what are the applications?

A: The Photon Mono M5s is compatible with a wide range of resins, including flexible and castable types. Flexible resins are great for printing parts that need to bend or stretch, such as seals, gaskets, or wearable items. Castable resins are used in jewelry making and dental industries, as they can be burned out of a mold without leaving ash, allowing for direct casting of metal parts. When using these specialized resins, adjusting the print settings accordingly is crucial to achieving the best results.

Q: How does the anti-aliasing feature work on the Anycubic Photon Mono M5s, and how does it improve print quality?

A: Anti-aliasing is a feature designed to smooth out the edges of your prints, reducing the "stair-stepping" effect on sloped or curved surfaces. It works by slightly blurring the edges of each layer, creating a gradient effect that results in a smoother overall appearance. This feature is particularly useful for models with intricate details or where a smooth surface finish is desired. To use anti-aliasing, simply enable it in the Anycubic Photon Workshop software before slicing your model. You can adjust the level of anti-aliasing to find the balance between smoothness and detail that works best for your print.

Q: What are the most common causes of failed prints on the Anycubic Photon Mono M5s, and how can they be avoided?

A: Common causes of failed prints include improper leveling of the build platform, incorrect resin settings (such as exposure time and layer height), and insufficient support structures for the model. To avoid these issues, ensure the build platform is leveled correctly according to the manufacturer's instructions before starting a print. Also, use the recommended resin settings provided by the resin manufacturer or start with the default settings in the Anycubic Photon Workshop software and adjust as needed. Lastly, ensure your model has adequate support structures, especially for overhangs and delicate parts, to prevent warping or detachment during printing.

Q: What safety precautions should be taken when working with resin and the Anycubic Photon Mono M5s?

A: Working with resin requires careful handling to avoid skin irritation or allergic reactions. Always wear gloves when handling uncured resin, and use a mask if you're sensitive to the fumes. Work in a well-ventilated area to minimize exposure to resin vapors. Avoid direct skin contact with the resin, and wash any exposed skin thoroughly with soap and water. If resin gets into your eyes, rinse immediately with plenty of water and seek medical advice. Always follow the safety guidelines provided by the resin manufacturer and the printer manufacturer.