3D printing, an emerging technology with a significant impact on the manufacturing industry, is no longer confined to the realms of industrial applications or research purposes. It has enabled users from the medical sector to automotive companies to create prototypes, complex shapes, and even final objects with a level of precision and customization that traditional methods couldn't offer. If you're new to this world of additive manufacturing, this guide is tailored to help you navigate the basics and get started on your 3D printing journey.

Key Takeaways:

- Understand the fundamental concepts of 3D printing, including the various technologies and materials used.

- Learn how to prepare a digital model for printing and the importance of print settings for a successful print.

- Discover the potential applications of 3D printing in various industries and the benefits over traditional manufacturing processes.

Understanding the Basics of 3D Printing

3D printing, or additive manufacturing process, is a method of creating a physical object from a digital model by adding material layer by layer. This is a major difference from subtractive manufacturing processes, which involve cutting away at a solid block of material to create an object. The most common form of 3D printing for beginners is Fused Deposition Modeling (FDM), where a print head extrudes thermoplastic material onto a print bed, creating the object layer by layer.

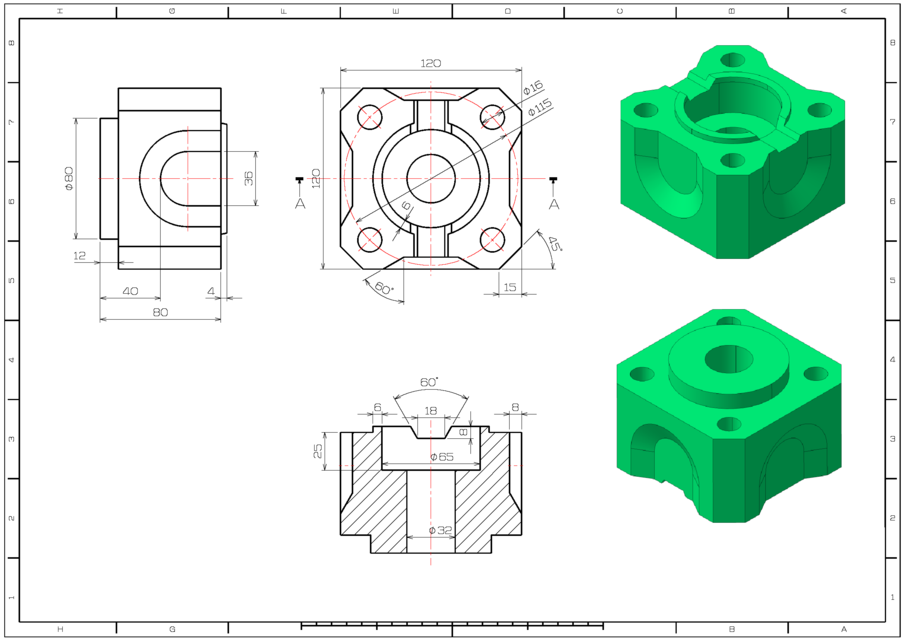

The first step in 3D printing is to create a design using computer-aided design (CAD) software. This digital model is then converted into an STL file, which can be understood by the printer. Slicing software takes this file and translates it into printing instructions, determining factors like print speed, layer height, and support structures necessary for complex geometries.

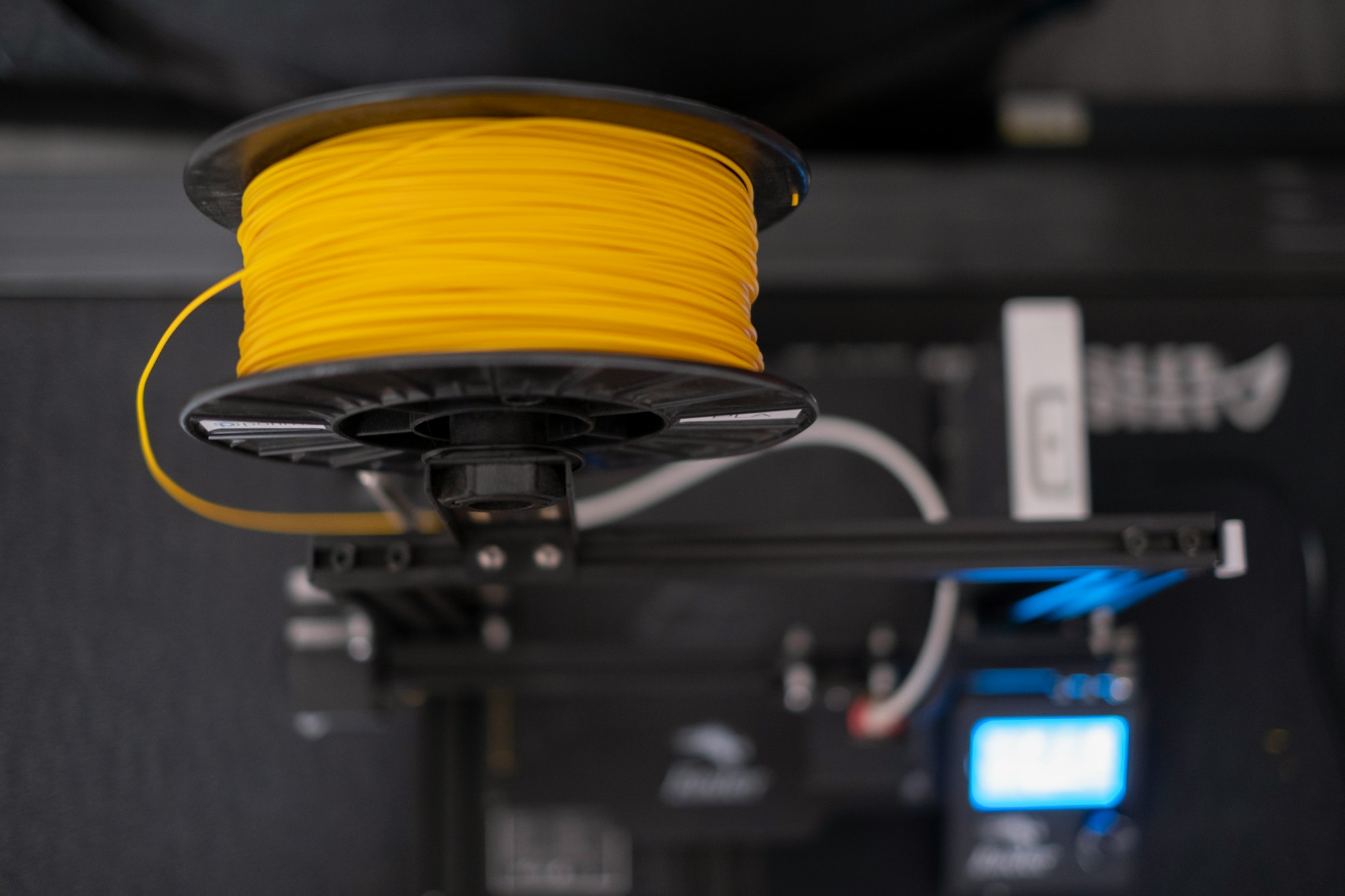

Choosing the Right Materials for Your 3D Project

When embarking on the journey of 3D printing, a guide for beginners often emphasizes the importance of selecting appropriate raw materials. Each material offers distinct advantages and challenges, affecting the final object's durability, flexibility, and appearance. For instance, ABS plastic is known for its strength and heat resistance, making it ideal for objects that might encounter high temperatures. On the other hand, PLA is a biodegradable material favored for its user-friendly properties and is excellent for those just starting out due to its lower bed temperature requirements.

The choice of material extends beyond plastics, with powdered material and metal options expanding the horizons of 3D printing. The SLS printing process, which utilizes a laser beam to sinter powdered material layer by layer, offers a high degree of precision and strength, suitable for more advanced technology applications. It's crucial to match the material properties with the intended use of the printed object. Online resources and communities can provide valuable insights into the experiences of others, helping to guide material selection for optimal print quality and functionality. Navigating the World of 3D Printer Software

When diving into 3D printing, a guide for beginners wouldn't be complete without discussing the pivotal role of computer software. User-friendly interfaces and powerful tools are the hallmarks of modern 3D printer software, which bridge the gap between your creative ideas and the physical object you aim to produce. Whether you're a hobbyist or a professional, the software you choose can significantly affect the quality and precision of your prints. It's essential to select a program that not only supports your printer but also matches your skill level and project requirements.

Computer-aided design (CAD) software, in particular, is a cornerstone of 3D printing. It allows you to construct and manipulate your designs in a virtual environment before sending them off to your 3D printer. For beginners, there are plenty of user-friendly CAD programs that offer intuitive interfaces and helpful tutorials. As you gain experience, you might gravitate towards more sophisticated software that offers advanced features for precision and complexity. Remember, the right software can make the difference between a project that's a joy to work on and one that's a chore.

The Journey from Raw Material to Finished Product

The transformation of raw material into a tangible, three-dimensional object is nothing short of magical. But it's not magic; it's rapid manufacturing at your fingertips. Understanding the journey from raw material to finished product is crucial for anyone looking to master 3D printing. This process begins with selecting the appropriate material that suits the object you intend to create. Different materials have unique properties and require different printing conditions, so it's important to do your research or consult with experts to make the right choice.

Once you've selected the proper raw material, your 3D printer takes over, layer by layer, to construct your design. This is where the rubber meets the road—or rather, where the filament meets the print bed. The excitement of watching your creation take shape is unparalleled. Imagine the pride of a person successfully walking away with a prototype they've designed and printed themselves. Whether it's a simple household item or a complex mechanical part, the journey from raw material to finished product is a rewarding experience that encapsulates the essence of 3D printing.

Optimizing Your Design with CAD Software

The heart of any 3D printing project lies in the design phase, where computer-aided design (CAD) software becomes an indispensable tool. CAD software allows for the meticulous crafting of digital models, which are then translated into physical objects through the 3D printing process. Beginners may find a steep learning curve when first navigating CAD programs, but many user-friendly options are designed with novices in mind. These programs often come with tutorials and online resources to help flatten the learning curve, enabling a person successfully to walk through the design process with confidence.

Advanced technology in CAD software has revolutionized traditional processes, allowing for intricate designs that were once impossible to achieve. The precision of CAD, combined with the capabilities of processes like fused deposition modelling (FDM) and laminated object manufacturing, empowers creators to produce complex and highly detailed objects. The FDM process, in particular, is popular for its efficiency and the quality of the created layer, which is extruded through a heated extruder. By mastering CAD software, designers can ensure that their technical knowledge is translated into high-quality printed objects that stand the test of both form and function.

Preparing Your First Print

Before you can watch your creation come to life, you need to prepare your printer and the design file. Ensuring first layer adhesion is crucial; a heated print bed and extruder can help with this. The ambient temperature can also affect the print, so some printers have an enclosed print area to maintain consistent conditions. Slicer software will allow you to add support material where needed, which can be removed after printing, to maintain the integrity of complex features or overhangs.

The choice of printing material also plays a role in the final quality. Common materials include PLA and ABS plastic filament, but other materials like powdered metal or resin can be used in more advanced techniques like selective laser sintering (SLS) or digital light processing (DLP). Each material has its own properties and requires different print settings to ensure a successful print.

Applications and Advancements in 3D Printing

The versatility of 3D printing has made it a valuable tool across various sectors. In the medical industry, it's used for creating prototypes of human body parts for surgical planning or even prosthetics. Automotive companies leverage 3D printing for rapid prototyping, reducing the time and cost associated with developing new models. In the developing world, 3D printing offers a cost-effective solution for producing necessary items on-site, reducing the need for expensive imports.

As technology advances, the printing speed and the ability to print with multiple materials simultaneously are improving. This opens up possibilities for more complex and functional objects to be printed, further bridging the gap between 3D printing and traditional industrial manufacturing. The additive manufacturing process is continually evolving, with research focused on new materials and methods to expand the capabilities of 3D printing.

Summary

3D printing is a transformative technology that has democratized the manufacturing process, allowing individuals and businesses to create complex and customized objects with relative ease. By understanding the basics of the technology, preparing your digital model correctly, and exploring the various applications, beginners can quickly become proficient in 3D printing. With its growing accessibility and user-friendly tools, 3D printing is poised to continue its significant impact on how we create and innovate.

FAQ Section

Q: What is the most user-friendly 3D printing technology for beginners? A: Fused deposition modeling (FDM) is generally considered the most user-friendly and widely accessible form of 3D printing for beginners. It uses a simple process of melting and extruding plastic filament to create objects layer by layer.

Q: Can 3D printing be used for creating functional parts? A: Yes, 3D printing can be used to create functional parts for various applications. With the right material and printing technique, parts can be made that are strong enough for end-use in the automotive industry, medical sector, and even in aerospace applications.

Q: How long does it take to print an object with a 3D printer? A: The printing time can vary greatly depending on the size, complexity, and the printing speed of the object. Smaller, less complex objects can take a few hours, while larger or more detailed prints can take days. The type of printer and the settings used also play a significant role in determining the print speed.